Aerospace Engineer

Projects

My favorite individual projects are listed below. All work shown was conducted solely by Charlie Fenske unless otherwise specified.

Most projects I've worked on for companies are trade secrets or have export restrictions. See my resume for basic descriptions of these projects.

Jan - Apr 2022

I think liquid rocket propulsion is the the holy grail of engineering. A liquid rocket engine's power-to-weight ratio is orders of magnitude greater than that of car or jet engines and they must be light and strong enough to survive the flight to orbit. There are areas within the injector and combustion chamber where the temperature differential is around -300F to 5000F within a few millimeters. Rocket engines are hard to design and build but I wanted to try anyway.

Typically, only governments, corporations, and large well-funded student teams with support from professors make successful liquid engines. My goal, however, was design, build, and test a liquid engine by myself in four months while taking 6 classes during my final semester at MIT. I used knowledge gained from my internships at SpaceX and JPL, from several textbooks, and advice from friends in the industry.

Since I only had enough time to make one engine, I decided to set very ambitious requirements. After a few trade studies, I decided that the engine should use liquid oxygen (LOX) and kerosene propellants (same combination as the Saturn V and Falcon rockets), produce 5kN (1120 lbf) thrust, and be mass optimized for flight. For propellant injection I designed a pintle type injector with fuel film cooling. Every part except the ablative thrust chamber assembly was designed to be reusable.

Since the only space I had on campus was my dorm room, I converted it to a bureaucracy-free mini rocket laboratory. Designing, building, and testing this engine (and test stand) took hundereds of hours to complete but I think I learned more from the project than from my 4 years at engineering school. Two weeks before I graduated, I successfully static fired my engine for 3 seconds. Developing this engine has been my most rewarding project yet and I plan to build larger and more efficient engines in the future.

The most time consuming and expensive part of building rocket engines is the system of tanks, valves, and sensors called the test stand. A test stand's main function is to deliver the cryogenic liquid oxygen oxidizer and kerosene fuel at the correct pressure and flow rate to the engine. The stand also has to withstand the thrust of the engine, remotely execute commands, record data, and mechanically shut down and vent pressure in the event of an anomaly or loss of power.

The test stand consists of the following subsystems:

-

High pressure panel to regulate and distribute the nitrogen pressurant gas to the tanks, fuel/ox purge system, and low pressure pneumatics

-

Insulated tanks with relief, vent, fill, and drain valves.

-

Liquid feedlines with valves modified for cryogenic oxygen service

-

Purge system to clear the engine and propellant lines of residual propellant after shutdown

-

Low pressure pneumatics system to provide gas to pneumatically-actuated valves

-

Control system programmed to actuate valves at the precise timing needed to fire a liquid engine

All of these components (even the tube fittings) are typically very expensive or not sold to consumers. I therefore had to buy most components from Ebay or make them myself. After 4 months of work, I was confident that the test stand was a safe system capable of firing liquid rocket engines. During the test of my first engine, the stand worked flawlessly from startup to shutdown. I expect this stand to fire countless more engines in the future.

Folding Surfboard for Air Travel

Dec 2021

I started surfing while working on SpaceX Starships in Boca Chica, Texas. When I moved to LA for an internship designing on SpaceX Raptor engines and valves, I was able to surf at the best breaks in the world. The only problem was transportation (and crowds). The following year, while a senior at MIT, I designed and built a folding surfboard that could fit in a checked suitcase for a trip to Costa Rica.

Dec 2018 - May 2019

As a Freshman at MIT, I was interested in designing and building a high power solid rocket engine in order to launch larger rockets. Since I only had my dorm room as a lab space, I decided to use a sugar and potassium nitrate propellant mix, which is significantly safer and cheaper than other propellants. Still, if I got caught there's a chance MIT would let me keep working just like a similar group of students at CalTech in the 30s. The engine was successfully static fired and was reusable immediately after the test.

Lightweight Electric Bike

May 2019

I built this bike (during freshman finals week) to transport me from my rental house in South Pasadena to JPL while I was interning there. The trip was 7 miles each way and the air temperature often reached 100F which was tough on the battery. The bike, like many JPL-built probes, has lasted an order of magnitude longer than expected and is still in use today!

Rocket with Live Video Link to the Ground

Nov 2018

Model rockets are fun but I've always wished I could watch what the rocket sees as it flies (just like the SpaceX live video feeds). I already had high power analog video transmission hardware from my FPV planes so I decided to build it. The rocket successfully launched and I was able to watch it ascend from two frames of reference!

Long Range FPV Model Airplanes

Long ago - Aug 2021 (for now)

For several years, I've been designing, building, and flying long range model aircraft. They have evolved a lot over the years. The most current designs are autonomous, can fly for at least an hour, cruise at >40 mph, and have 10s of miles of range.

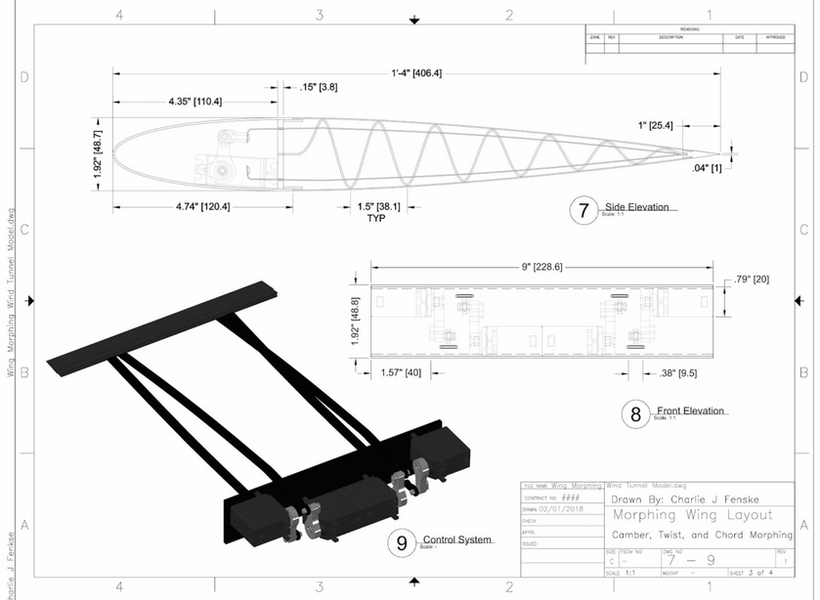

Morphing Wing Technology Demonstrator Model

Mar - May 2018

I spent much of my senior year of high school inventing a composite morphing wing (US11203409B2). After developing the prototype, I designed and built a model aircraft using the morphing wing design as a technology demonstrator.

Geomteric Morphing Wing with Adaptive Corrugated Structure (US Patent US11203409B2)

Sep 2017 - May 2018

I spent much of my senior year of high school inventing a composite morphing wing. It can independently change shape in chord length, camber angle, and twist angle. An aircraft with this technology can optimize its wing shape real time to increase aerodynamic efficiency at all operating points. The design was later patented pro bono from a prize I won at the state science fair at MIT.

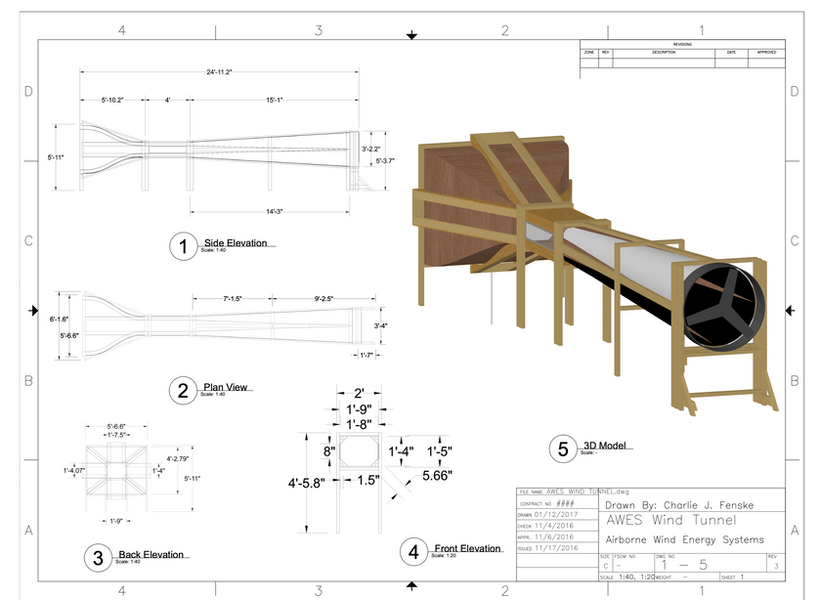

Wind Tunnels

Sep 2014 - May 2017

Several of my high school era projects required wing tunnels. I didn't have access to wind tunnels so I built one myself. Actually, I built three, but each replaced the last and had better capabilities. The final wind tunnel was over 25 feet long, had a lift/drag force balance, pressure tap sensors, and a turbulence intensity less than 5%.

Airborne Wind Energy System Glider

Oct 2016 - May 2017

For my junior year science fair project I designed and optimized a flight vehicle configuration for airborne wind every systems. Analytical software tools, such as XFOIL, were used with wind tunnel testing. The wind tunnel models were 3D printed with pressure tap channels routed through the internal structure. The pressure data was used to determine an optimal location for propellers airframe elements such as propellers.

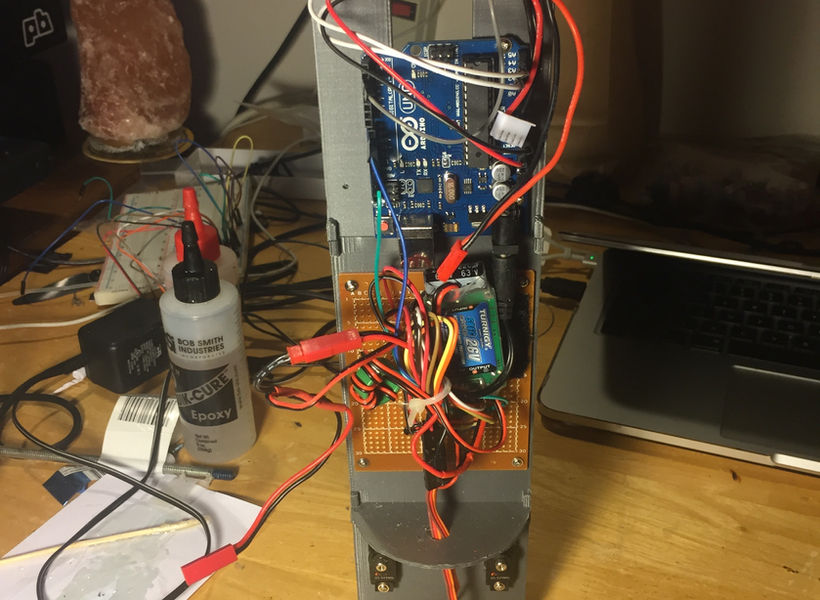

Roll-Stabilized Rocket

Feb 2016

As part of my sophomore science fair project, I designed, built, and tested a roll-stabilized rocket. The control system was contained in a 3D printed module that could be spliced into any 3" diameter rocket airframe. The control surface consisted of two canard fins connected to servos. A quadcopter board, running a PID controller, calculated the fin position. I hope to revisit this project someday since I didn't know much about controls at age 16. (I'd also like to put the 3 controls classes I had to take at MIT to good use.)