Aerospace Engineer

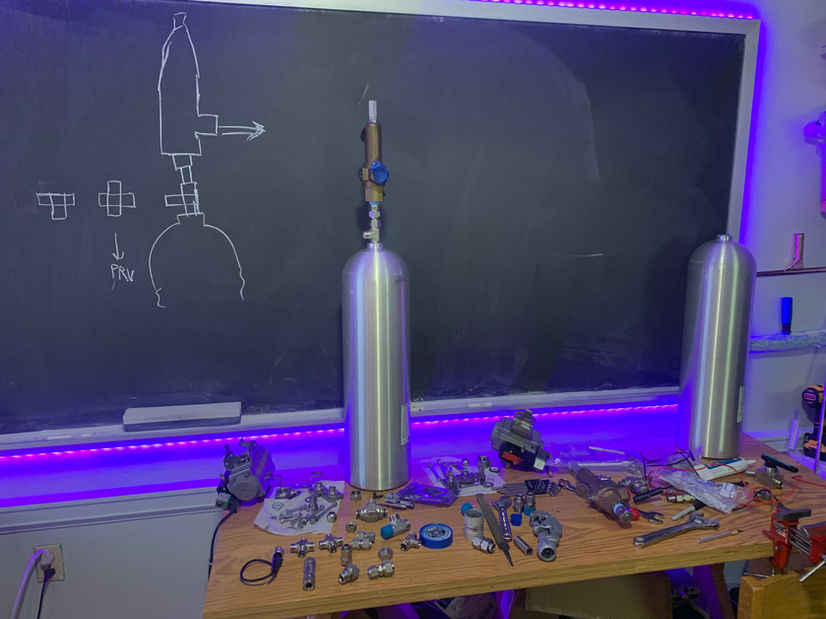

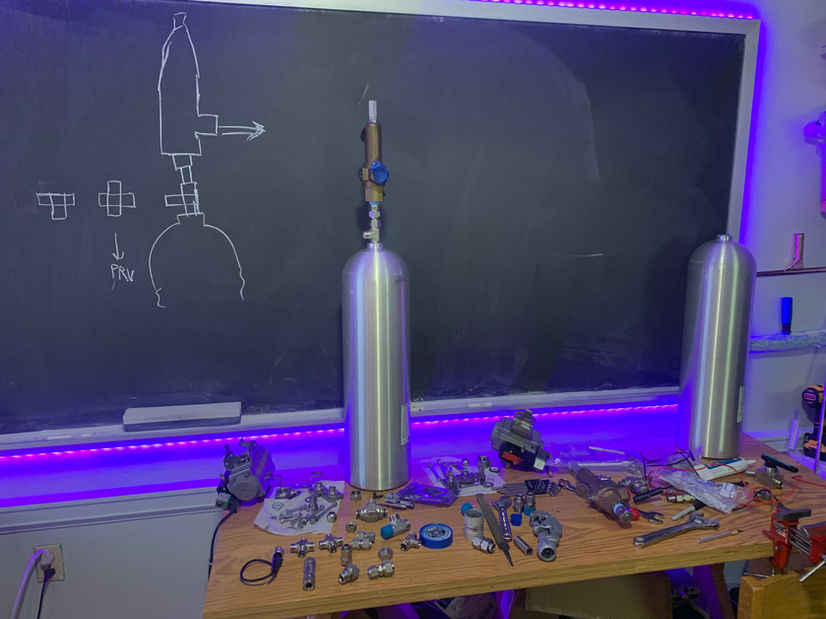

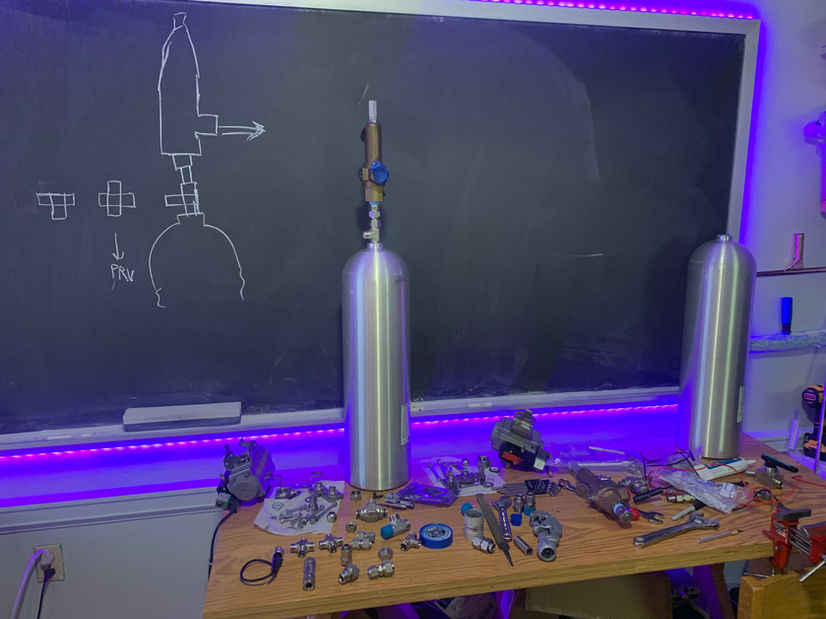

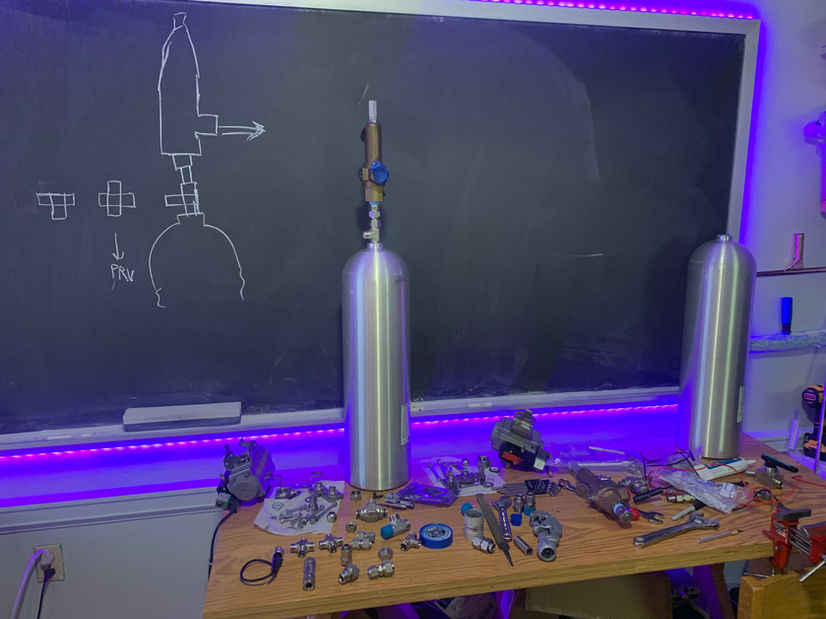

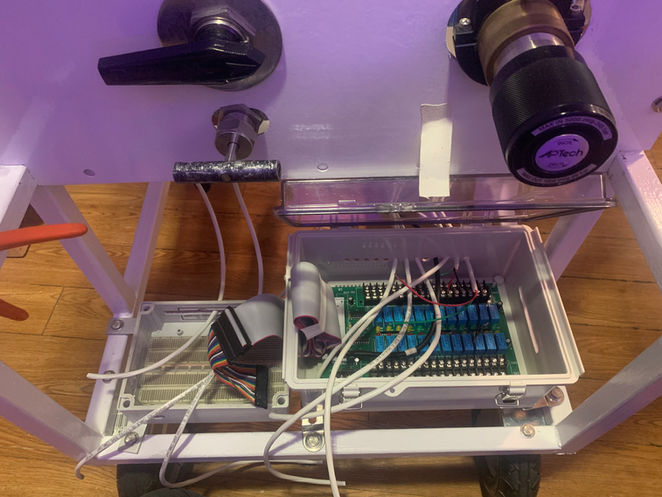

Liquid Rocket Engine Test Stand

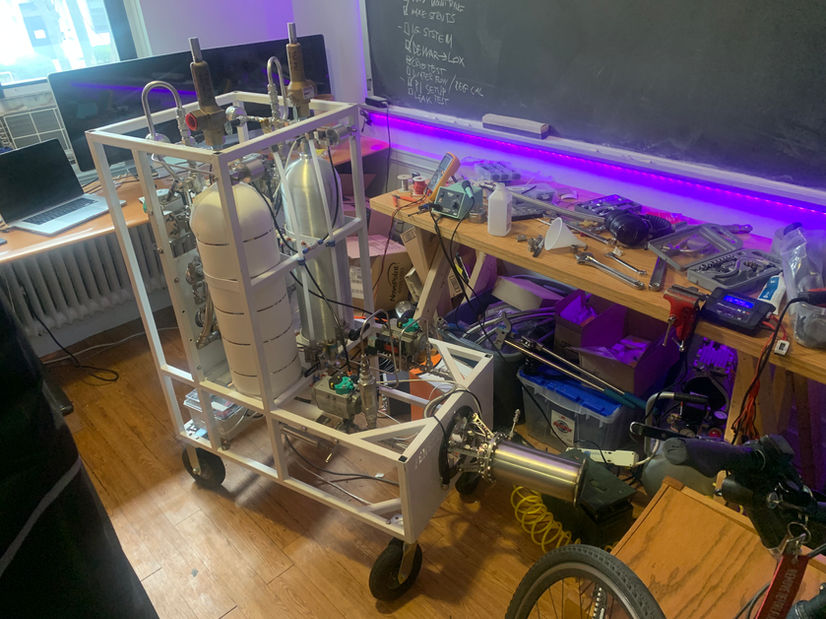

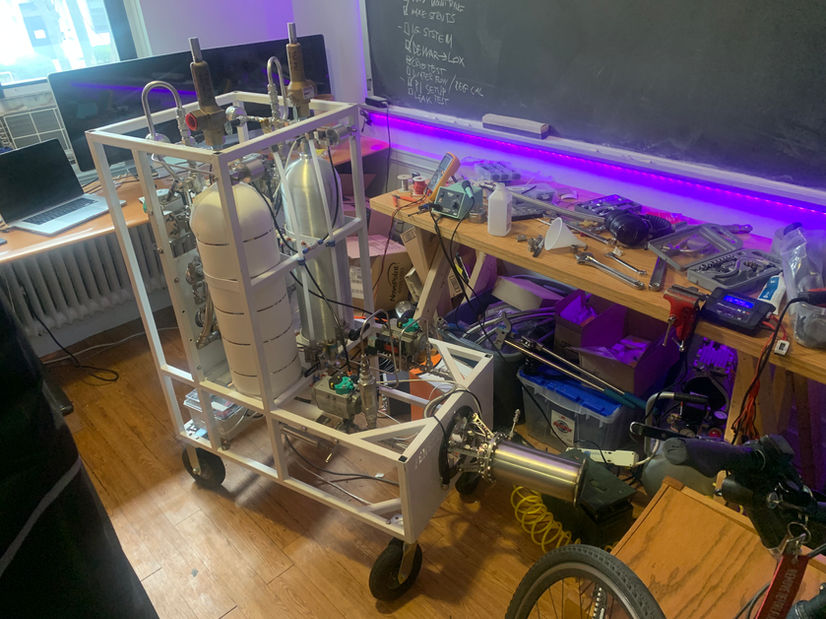

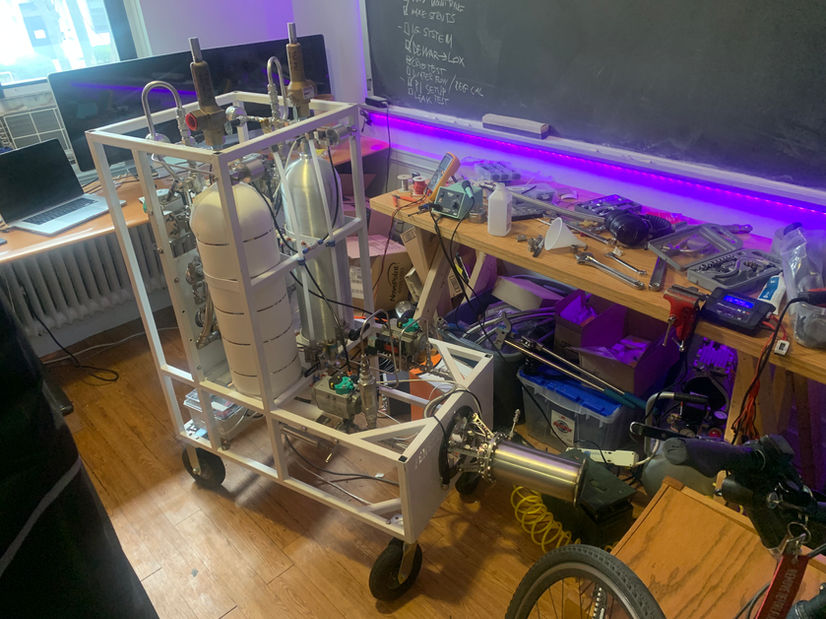

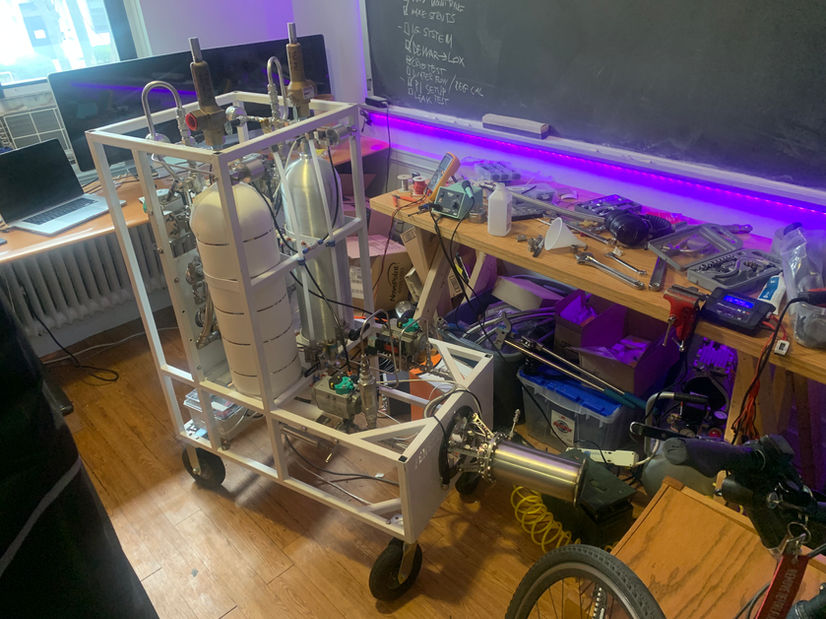

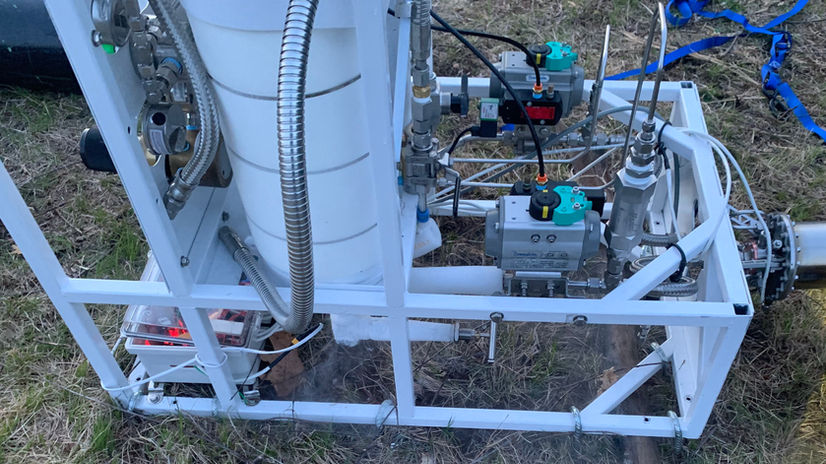

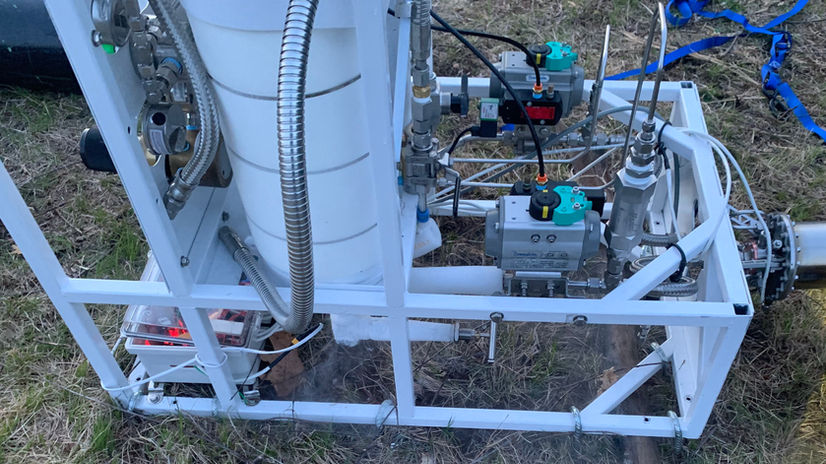

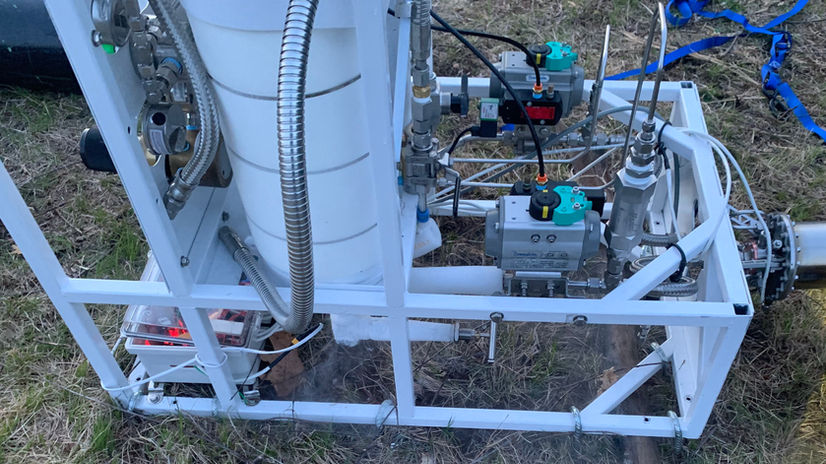

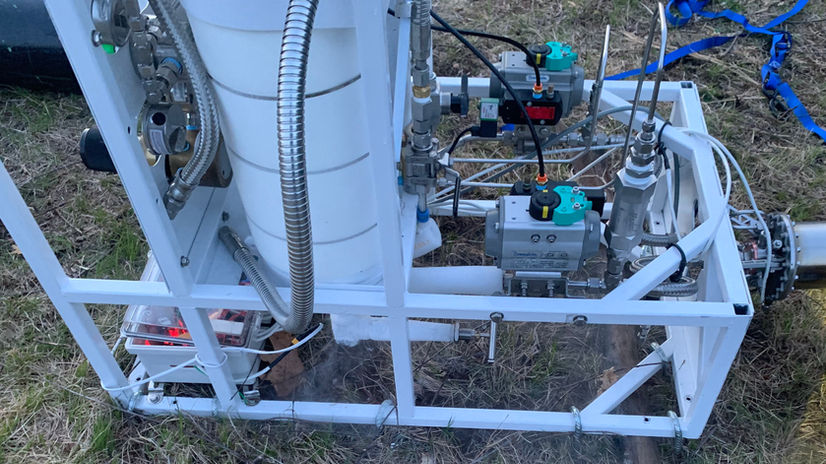

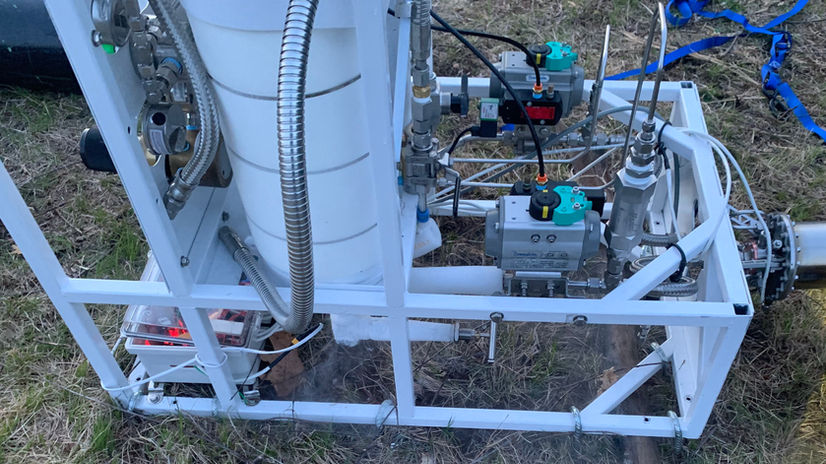

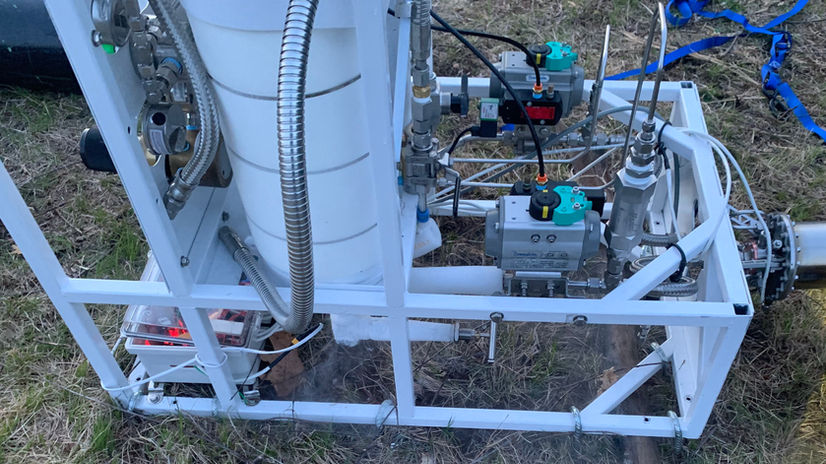

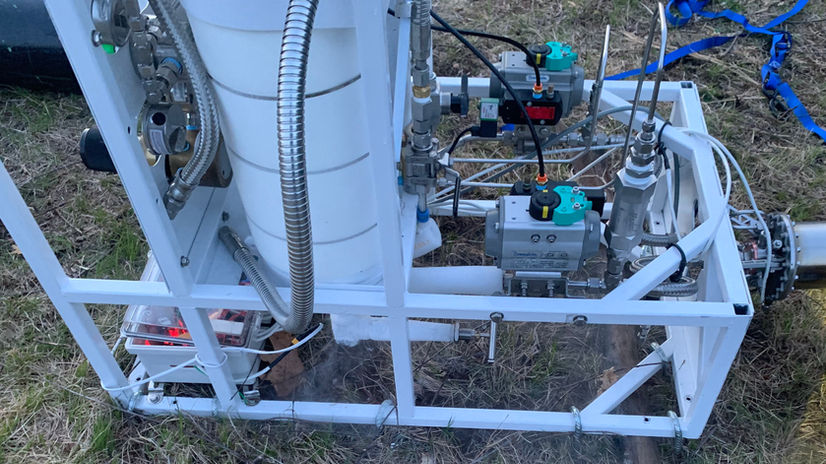

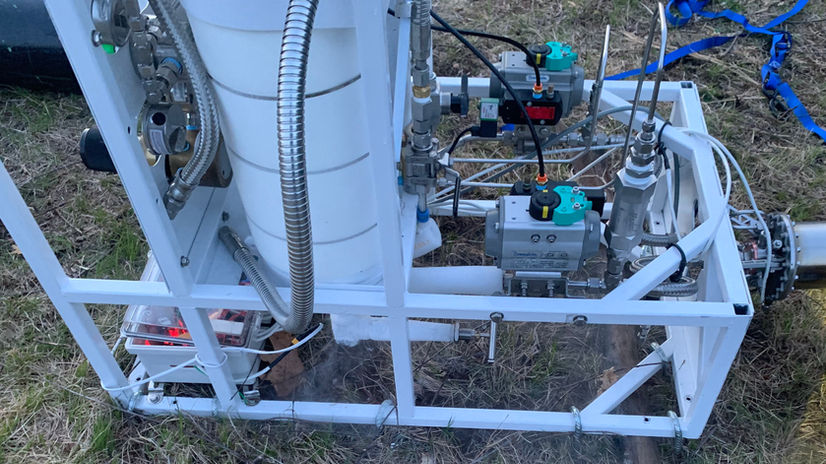

The most time consuming and expensive part of building rocket engines is the system of tanks, valves, and sensors called the test stand. A test stand's main function is to deliver the cryogenic liquid oxygen oxidizer and kerosene fuel at the correct pressure and flow rate to the engine. The stand also has to withstand the thrust of the engine, remotely execute commands, record data, and mechanically shut down and vent pressure in the event of an anomaly or loss of power.

The test stand consists of the following subsystems:

-

High pressure panel to regulate and distribute the nitrogen pressurant gas to the tanks, fuel/ox purge system, and low pressure pneumatics

-

Insulated tanks with relief, vent, fill, and drain valves.

-

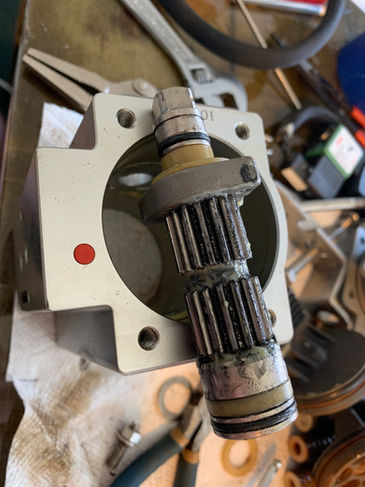

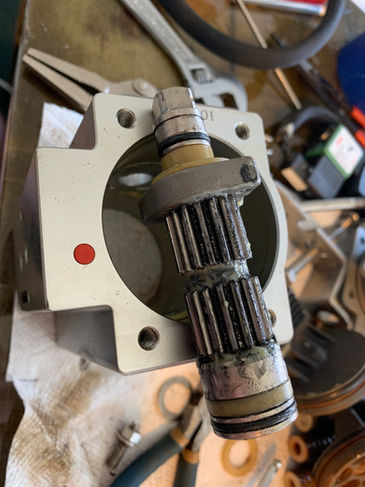

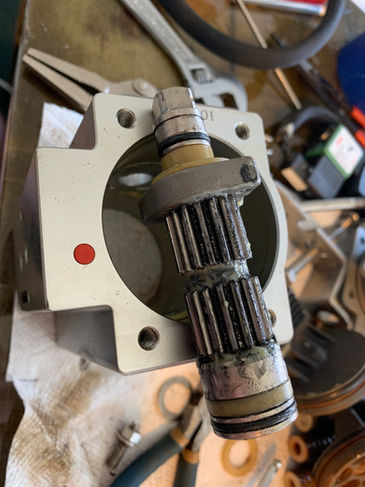

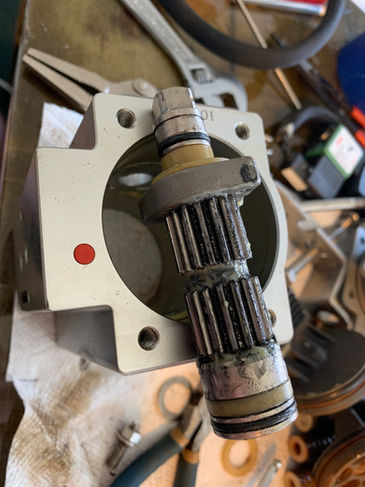

Liquid feedlines with valves modified for cryogenic oxygen service

-

Purge system to clear the engine and propellant lines of residual propellant after shutdown

-

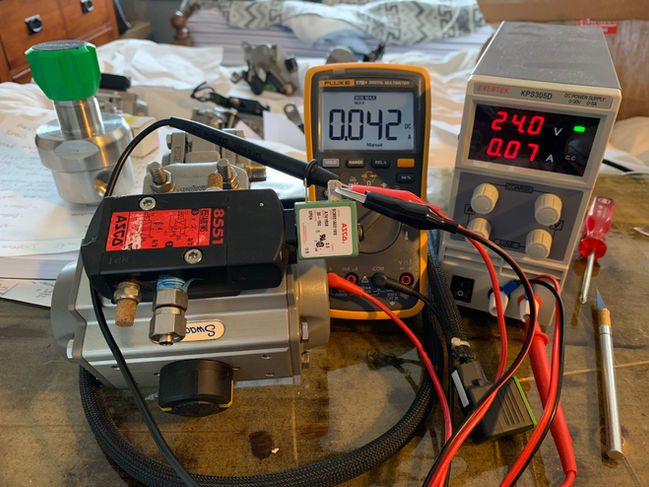

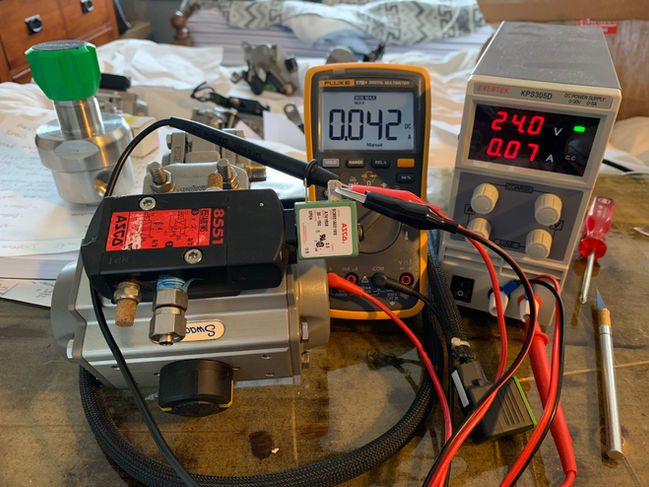

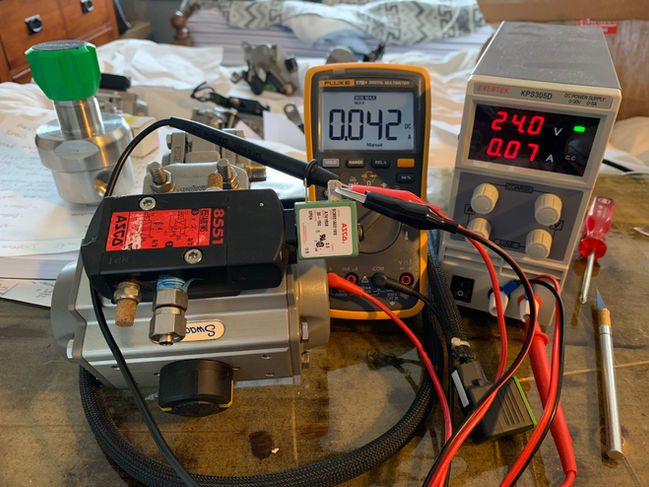

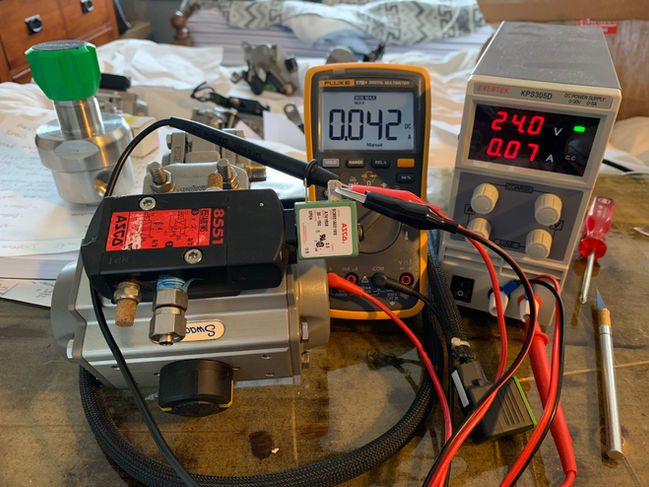

Low pressure pneumatics system to provide gas to pneumatically-actuated valves

-

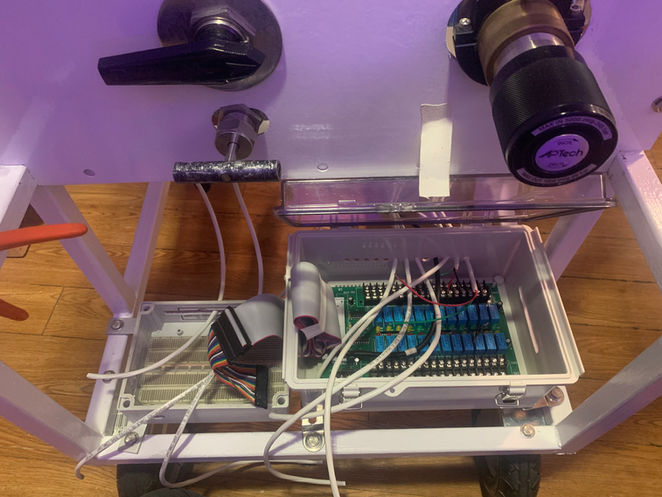

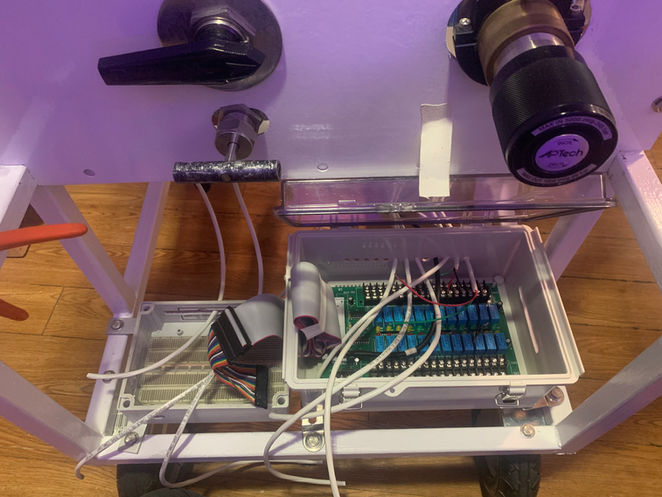

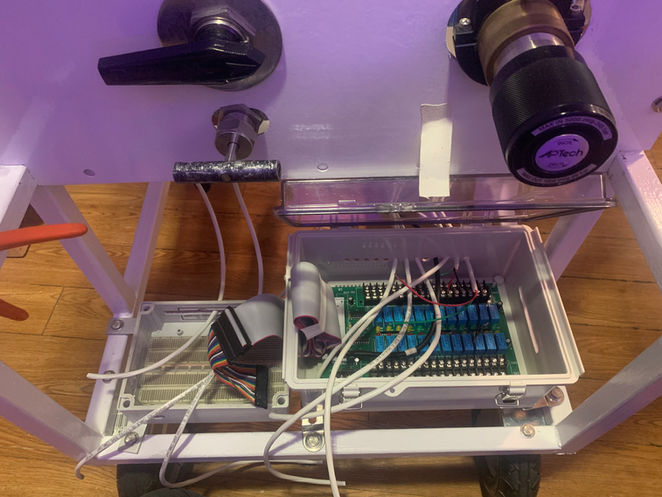

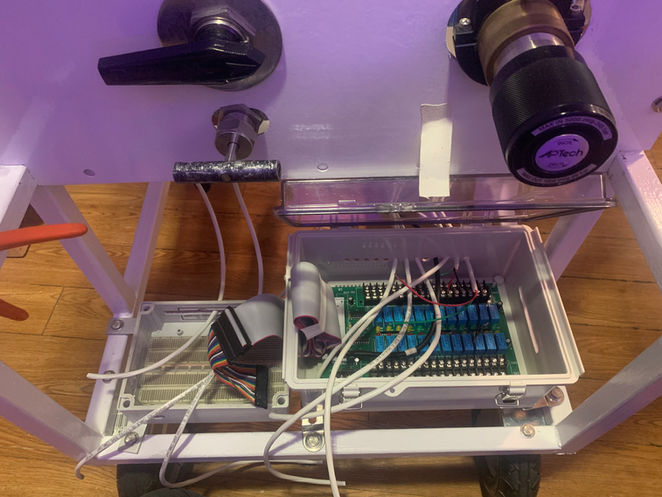

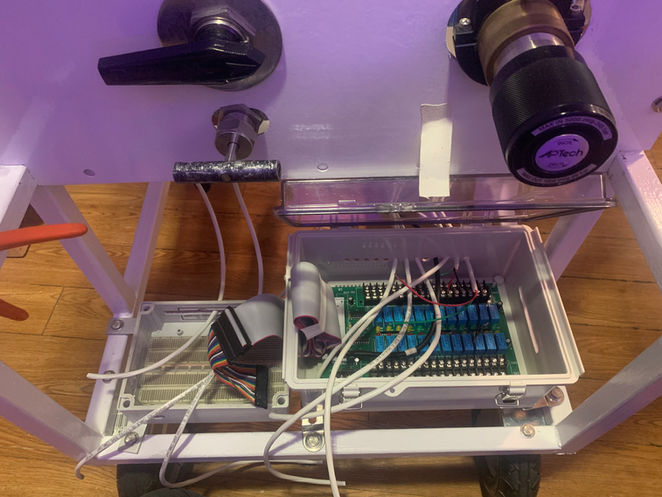

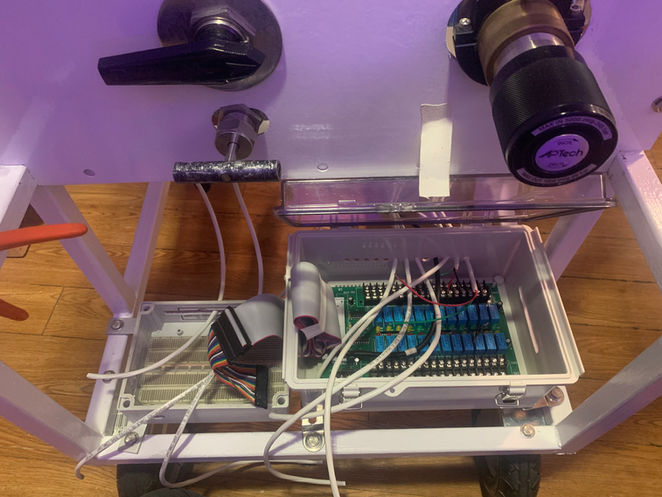

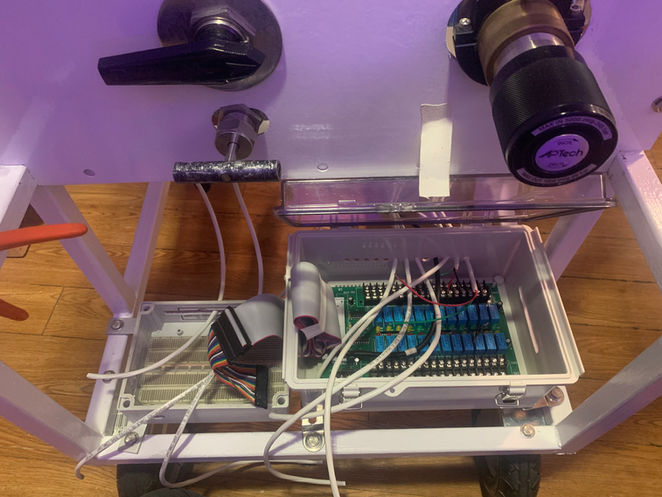

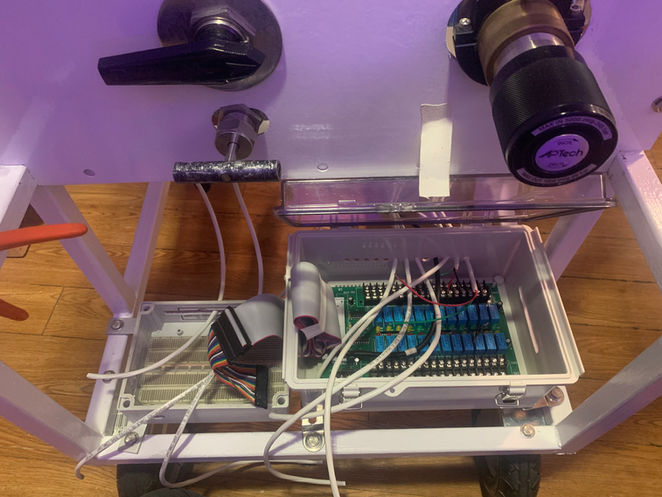

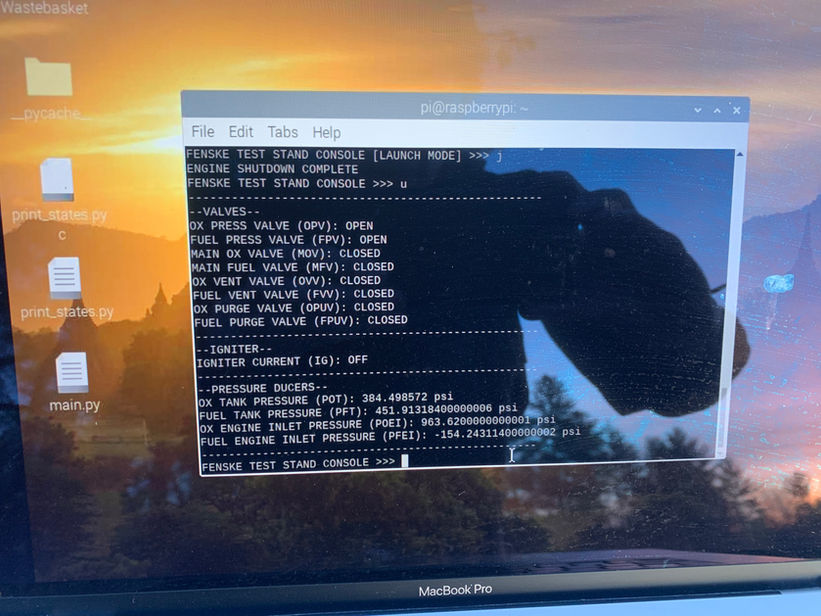

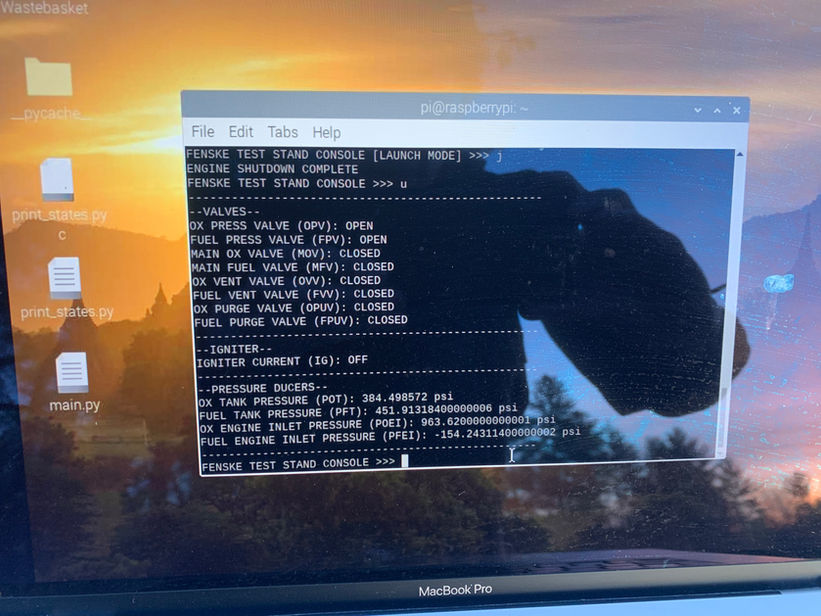

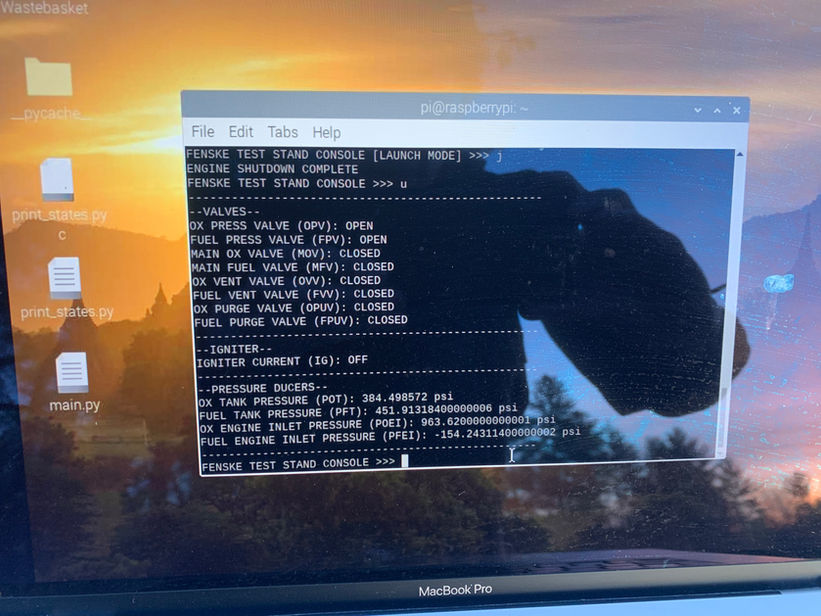

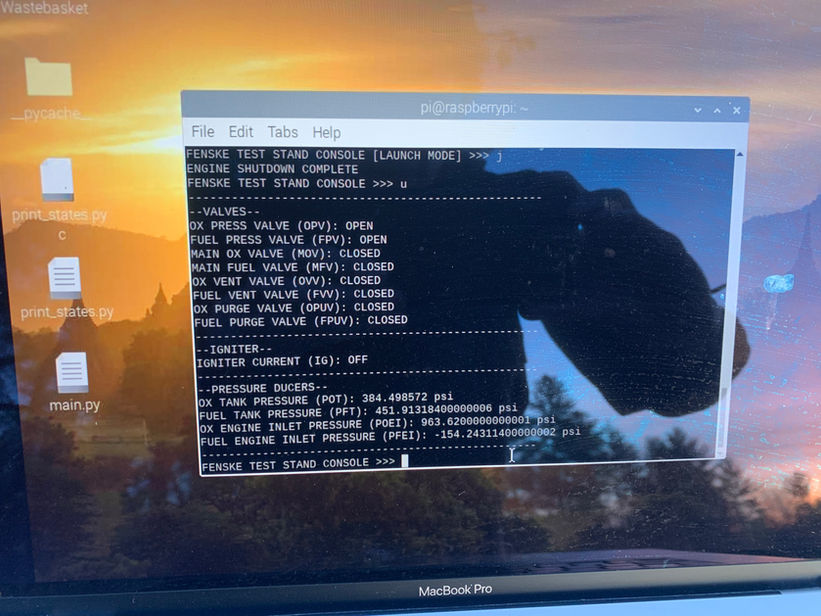

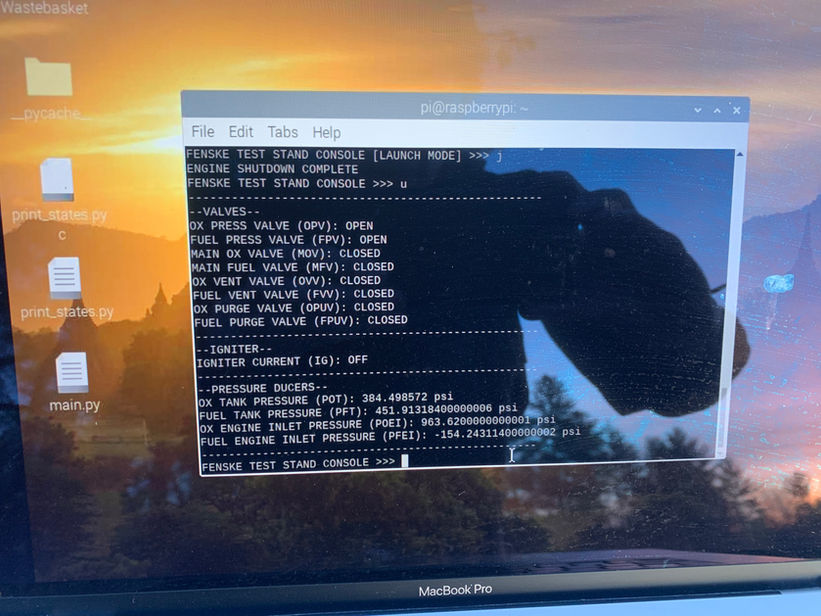

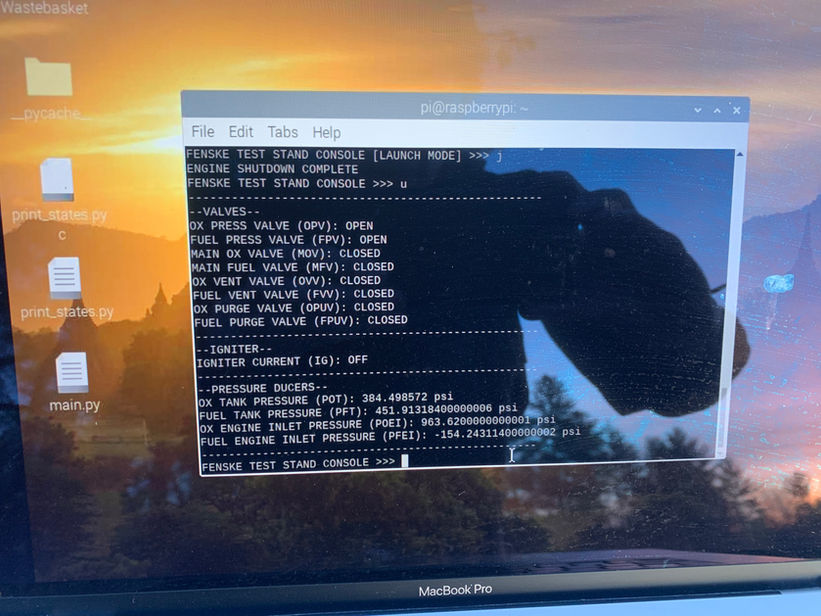

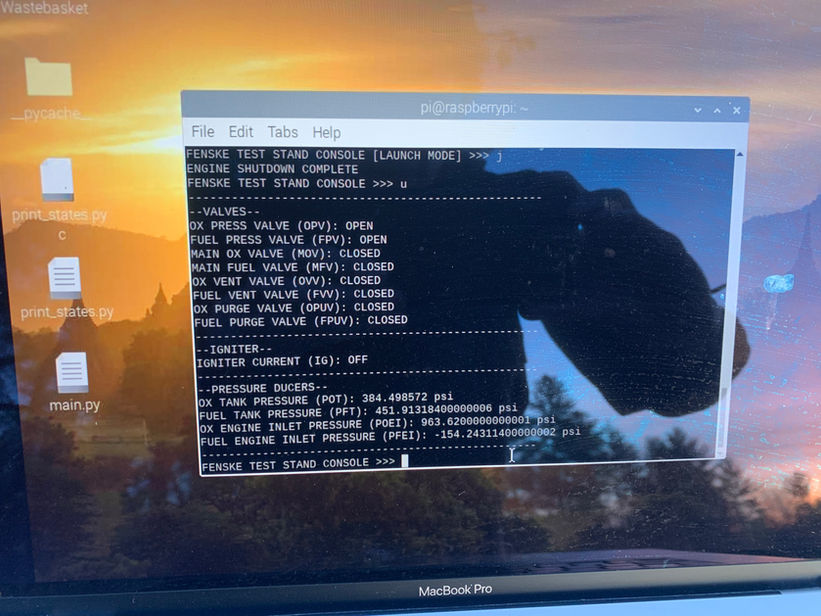

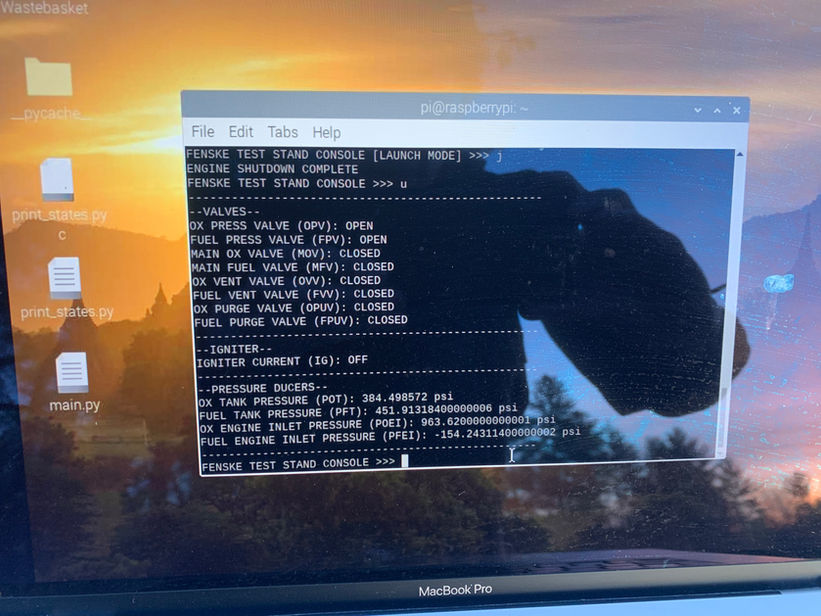

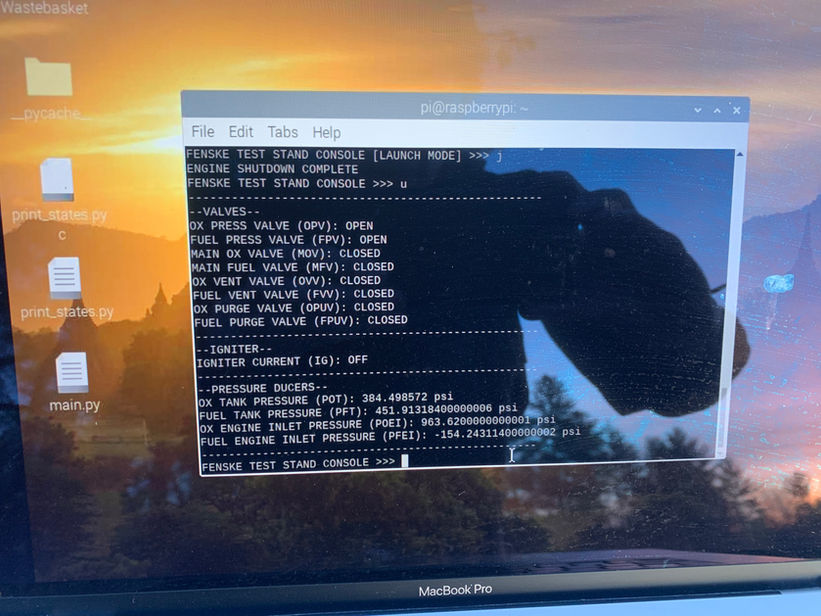

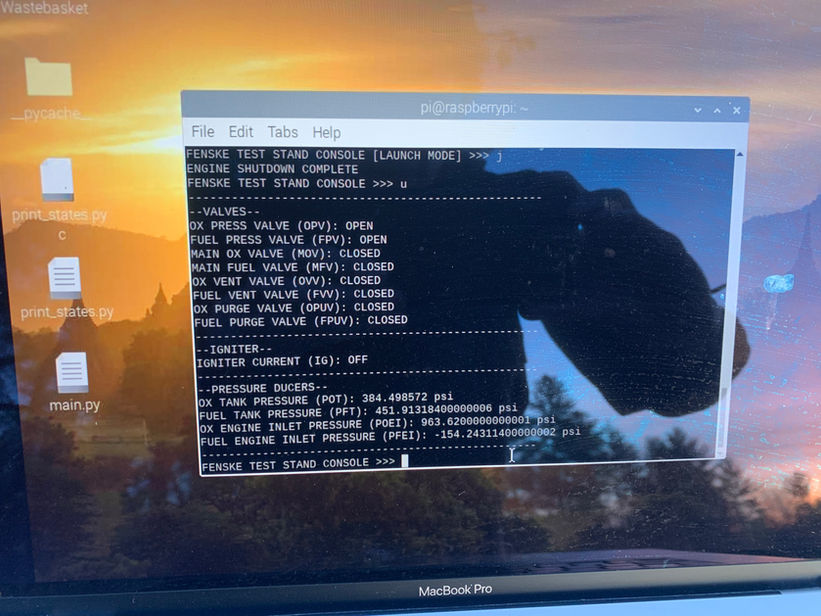

Control system programmed to actuate valves at the precise timing needed to fire a liquid engine

All of these components (even the tube fittings) are typically very expensive or not sold to consumers. I therefore had to buy most components from Ebay or make them myself. After 4 months of work, I was confident that the test stand was a safe system capable of firing liquid rocket engines. During the test of my first engine, the stand worked flawlessly from startup to shutdown. I expect this stand to fire countless more engines in the future.

Static Fire Video

Part I. Fluid System Development

Part II. Test Stand Model

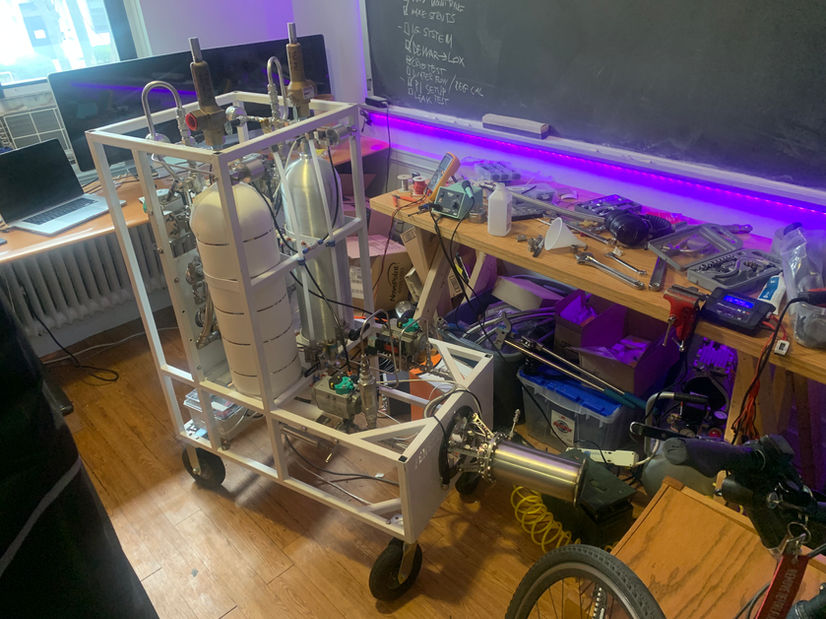

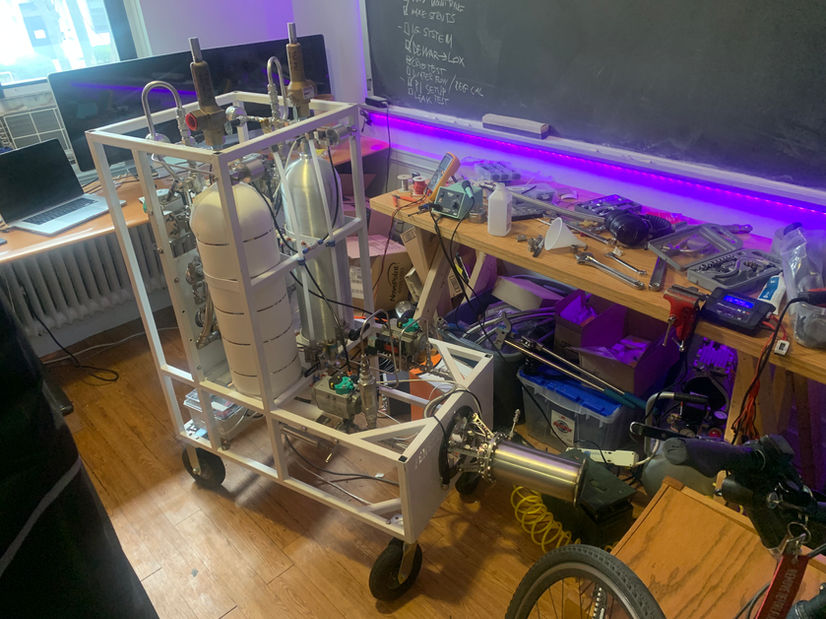

Part III. Manufacturing and Integration

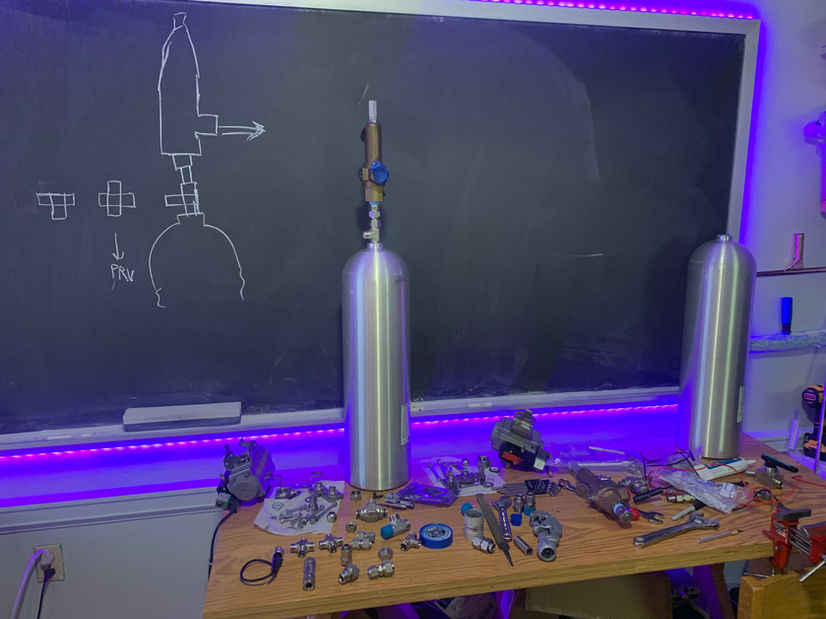

III.i. Fluid System Components

III.ii. Frame Weldment

f

III.iii. Propellant Tanks

III.v. High Pressure Panel

III.iv. Tank Press System

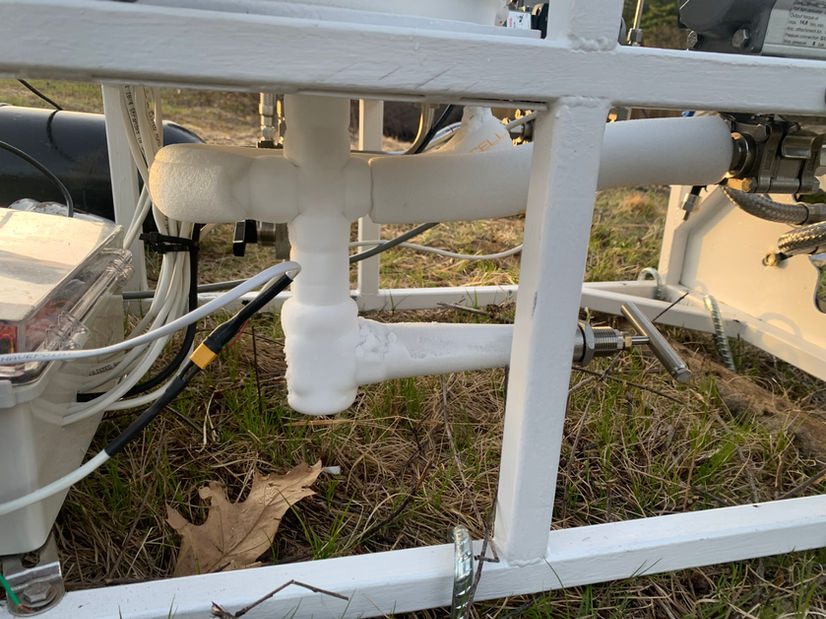

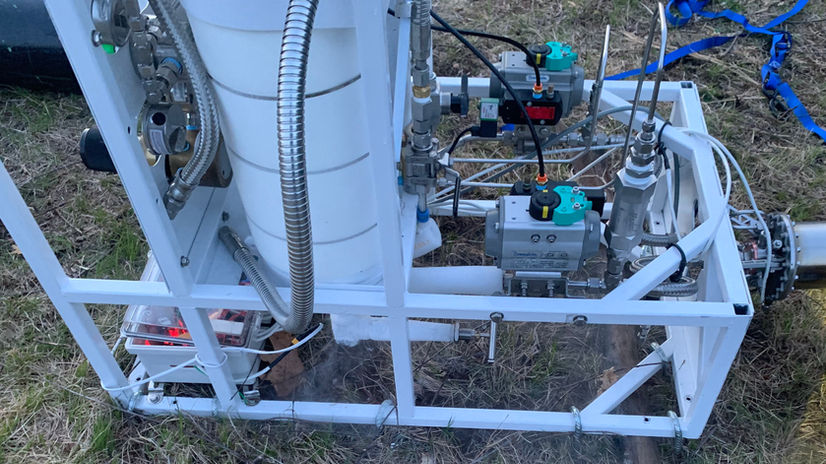

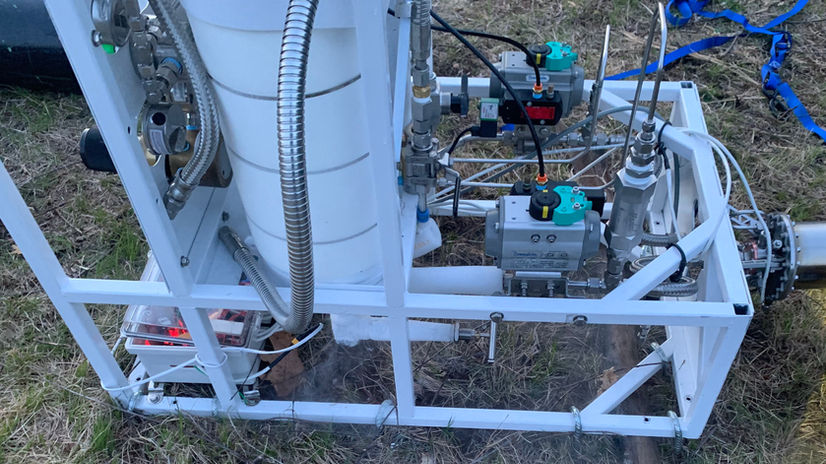

III.vi. Main Propellant Feedlines

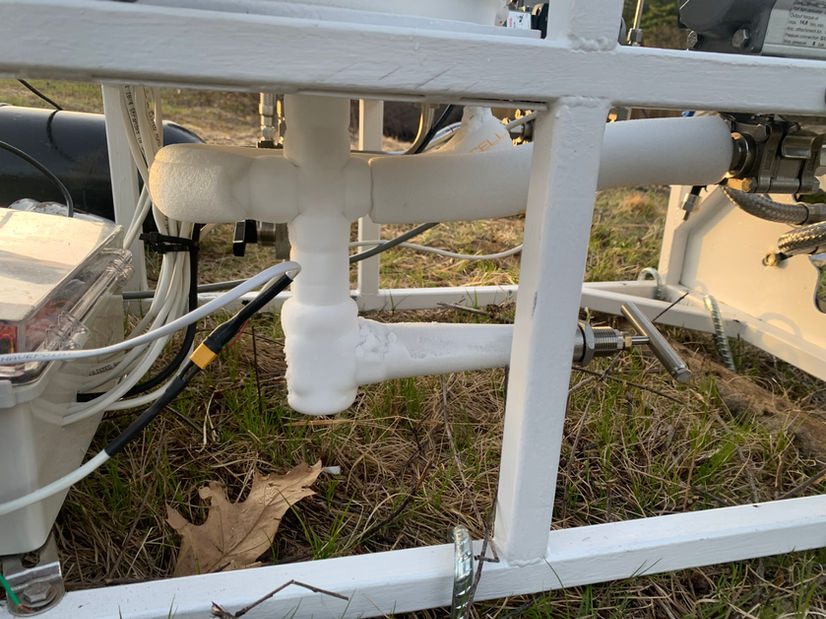

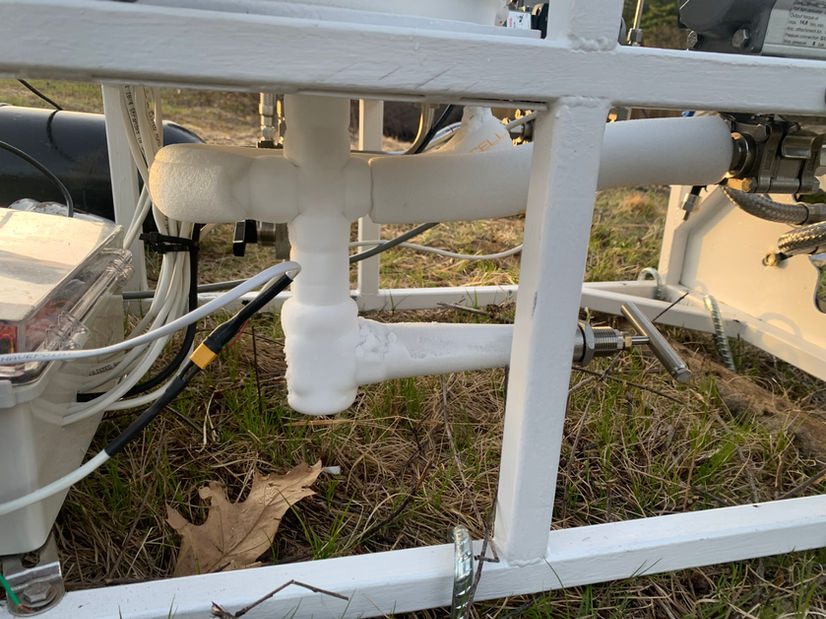

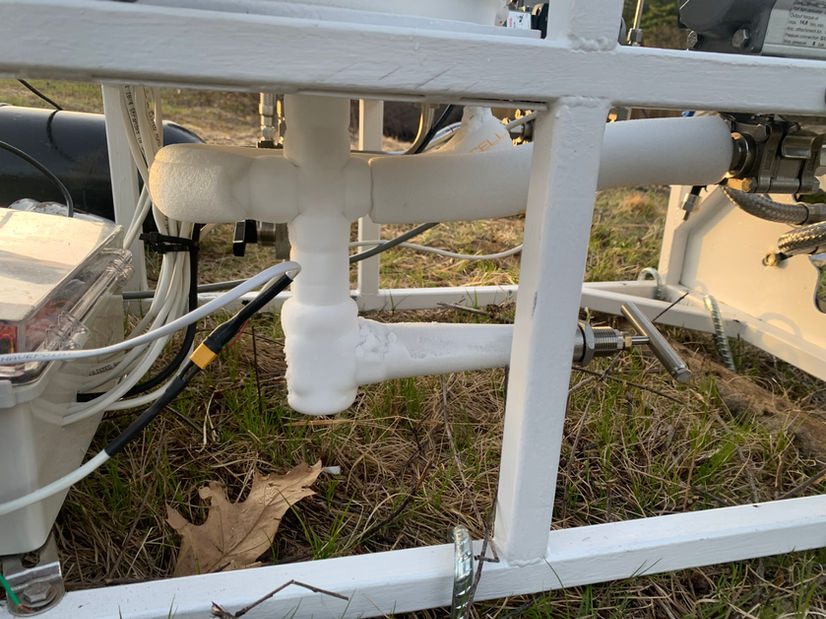

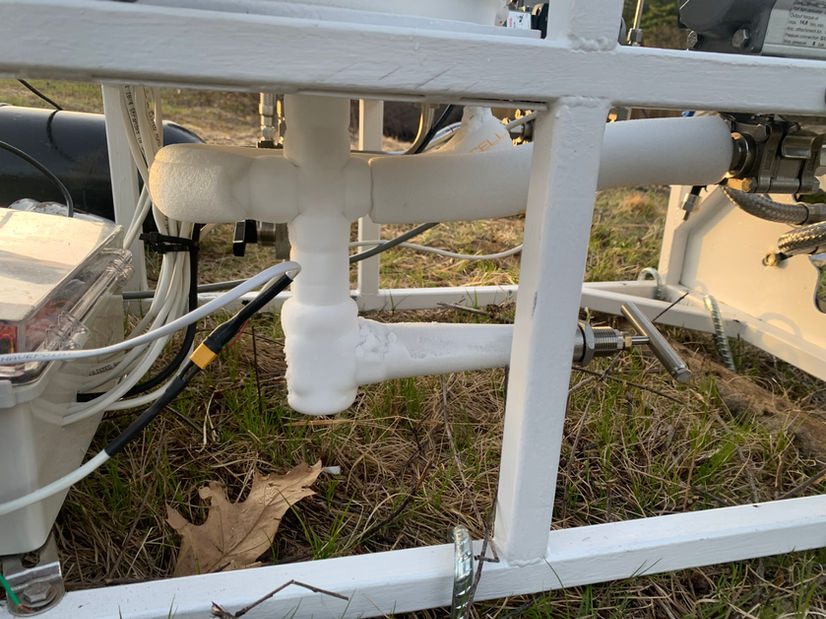

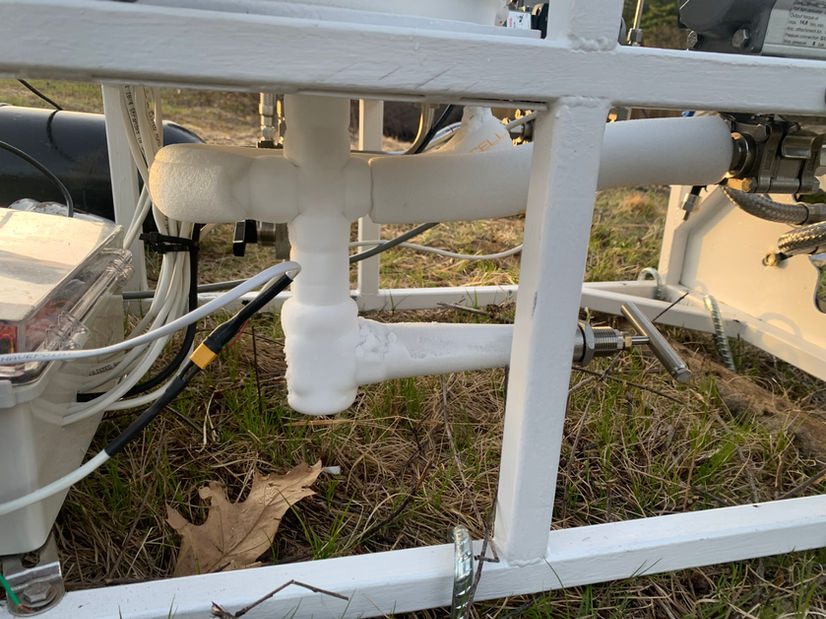

III.vii. Propellant Purge and Pneumatics Systems

Part IV. Control and Instrumentation

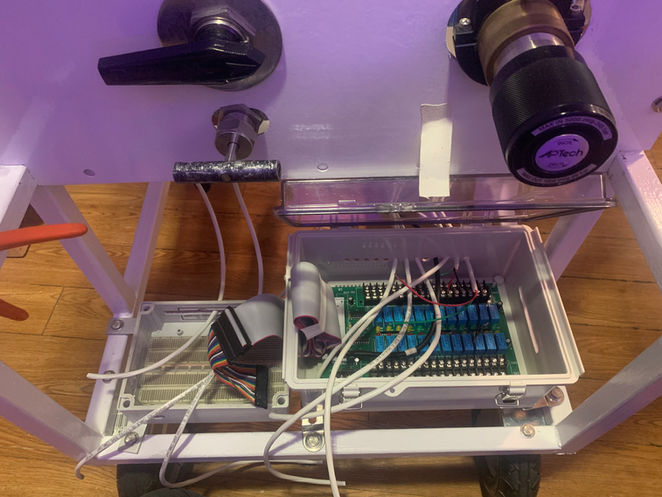

IV.i. Avionics

IV.ii. Control Software

Part V. System Characterization

V.i. Relief Valve Setting

V.ii. Fluid System Characterization

V.iii. LOX Dewar

Part VI. Hot Fire Testing

VI.i. Prop Load

VI.ii. Hot Fire